Catercall boasts an unrivalled reputation in the food service industry for providing first rate service and customer satisfaction.

Our dedicated team of fully qualified engineers and office support team are here to support your catering operation, they hold all major accreditations and qualifications to enable us to work safely and professionally in your kitchen. We are strategically located across the country enabling us to react promptly.

Operations Manager at Catercall, Richard Jeffryes, talks through what safety features you need to look out for and keep on track of in a mobile kitchen unit to prevent dangerous and potentially devastating incidents from occurring.

The responsibility and requirement to understand features within a mobile unit is far more important than with a permanent kitchen, and as such, the planning, layout and equipment choices you make are vital if you are to operate safely and legally.

A permanent kitchen has powerful extraction systems, better levels of ventilation and auto safety devices supported by back up appliances. Furthermore, you have the option of more powerful, heavy duty appliances. The basics of gas safety remain the same, appliances must be fit for purpose, gas pipework and valves must be gas tight and the extraction and ventilation of the products of combustion is essential for your safety. However, this is where the similarities end between permanent kitchens and mobile units.

Unlike natural gas, mobile units run on Bottled LPG and operate at a high pressure, making then unpredictable. The flame is faster and harder to set, meaning maintenance of the gas air mix is crucial if you are to get the perfect flame. For the operator, the perfect flame should be blue and constant; yellow flames or flame tips on the other hand indicate the presence of Carbon, which can also be recognised by black stain on pots. If you see this, it’s a sign of a combustion and must be rectified immediately for everyone’s safety.

As a simple guide, appliance choice is critical

If an appliance fails you lose trade, so don’t be governed by price. Instead, choose from experience or peer reviews. Heavy duty appliances are unlikely to be suitable; appliances should be medium duty and from a recognised brand. Interlocks and ECV’s found in permanent kitchens are a luxury but not mandatory, however pipework is important, so ensure flexible hoses are date stamped and conform to legal requirements. Local isolation ( emergency shut off ) must be visible and easy to access, however it does not have to be automated.

Counters and appliance stands will require the skills of a good fabricator, and ideally, steel frame with stainless finish are best. Burnished or chequer plate alloy also works well. On the basis that trailers are bespoke installations, on detachable LPG supplies the pipework does not have to be laid in by a gas safe engineer, however, it does have to be of a regulation grade and size. The LPG set up, cannisters, and regulators would typically be installed by the specialist gas supplier, with bottle isolation and connection on a simple copper /steel threaded connection to supply pipework. The final connection, appliance commissioning, safety testing and any appliance, burner or valve maintenance must be undertaken by a Gas Safe Registered Engineer

The importance of gas inspections

Within a van you have two tangible risks. Firstly, combustion and gas escape; this needs little explanation because it’s visual and destructive. Secondly and potentially the highest risk is products of combustion, or to be more precise, incomplete combustion. In simple terms this is Carbon Monoxide, a silent killer which has no odour. Whilst gas tightness and appliance performance are important, the signs that indicate the potential for Carbon Monoxide feature highly on an inspection. The means of eradication are to ensure a blue flame is produced at all burners, at all times, and extract and ventilation is available and fit for purpose. Pass/ Fail confirmations are made on the following points: ventilation, operating pressure, flame failure protection, overall visual condition, chimney performance, air flow, and spillage (this refers to POC’s – products of combustion) remaining within the cabin.

Annual safety inspections are mandatory

Frankly, operators who do not instruct you are reckless, and potentially un-insured. The inspection CP44 Mobile catering van specific gas safety certificating, is easy to arrange, but must be undertaken by an engineer with correct Gas Safe Registration CoNGLP1CMC, in addition to ComCat registration. The responsibility does not end there, regular monitoring (Risk Assessment) by the operator is advisable, and would include the following questions:

– Are all flames blue?

– Are the flames consistent?

– Is the shut off accessible?

– Is the hose in good order?

– Is black soot present? (sign of carbon)

– Is moisture present? (sign of carbon)

– Are ventilation ports blockage free?

– Is extract system functioning?

Has anyone reported headaches, dizziness, tiredness, poor balance, nausea etc.? (signs of carbon monoxide)

For more information on Catercall, visit their website.

Featured Training

Featured Training

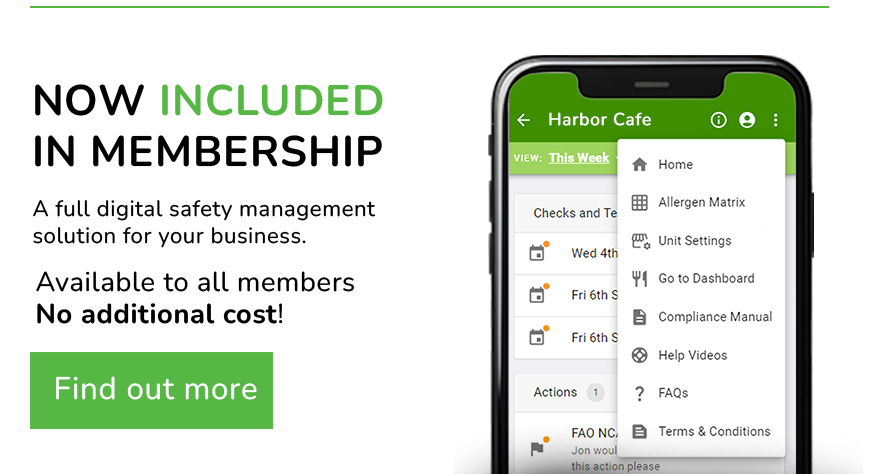

OUR MEMBERSHIP

We're here to help make your catering business a success. Whether that be starting up or getting on top of your compliance and marketing. We're here to help you succeed.

Want our latest content?

Subscribe to our mailing list and get weekly insights, resources and articles for free

Get the emails